About Company

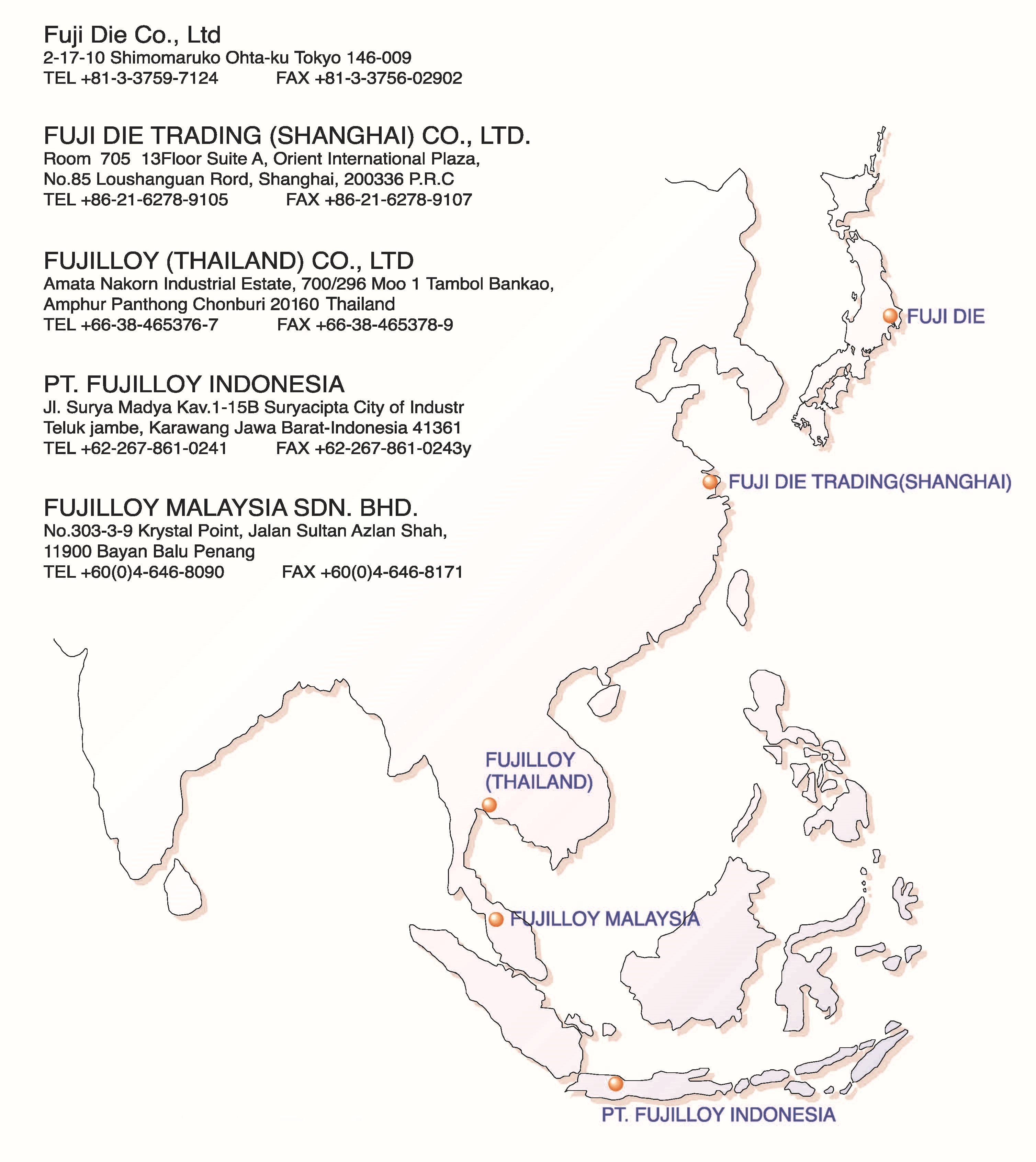

Fujilloy (Thailand) Co.,Ltd was established the year 2003 by Fuji Die Co., Ltd. from Japan

Everything For The Customer

Fujilloy (Thailand) Co., Ltd. was established the year 2003 by Fuji Die Co., Ltd. from Japan who held 100% share in response to the increased demand of Carbide tool with high wear-resistance in Thailand.

Throughout the rapid development in technology or new innovation in Thailand, the high quality samples and tools are required in many industries. Fujilloy has been the product provider in Carbide tool with high resistance to wear since then.Besides Carbide material products, Fujilloy also offers Ceramics material to meet the demands of their customers.

Fujilloy (Thailand) Co., Ltd. strongly believes in the same concept as Fujilloy Japan. All the employees have strong will, together work diligently and delicately on their physical and mental to meet the customers’ satisfactions.

Nowadays, majority of the product by Fujilloy are tool (die and plug) for tube forming altogether include tool for forming circular cross-section parts. Nevertheless, since March of 2012, the company will move to a new manufacturing site in Amata industrial park and will be capable of manufacture tools for more sophisticated workpieces.

|

|---|

FUJILLOY

Our Company

○ If there is human, there is Fujilloy – we are determined to give the most happiness to our customers.

○ Blended technologies with hearts – Human technology – together with believed hearts of the skilled workers, make us continuously capable of creating high precision workpieces in submicron.

○ Selection of the appropriate advanced technology. To achieve the highest efficiency and accuracy in production.

○ Development of materials. To provide a choice of powders that best suit the product and its future use.

○ Development of press forming, forming and sintering technologies, To improve product quality through the innovative use of cutting edge equipment by our skilled engineering staff.

○ Development of grinding and cutting technologies in product completion. To deliver better finished products through the original application of cutting edge equipment under the guidance of Fuji Die's expert engineers.

○ Uncompromising final inspection. To satisfy the most demanding of our customers by using the most advanced equipment, such as a roundness measuring device with a 20, 000 times magnification rate.